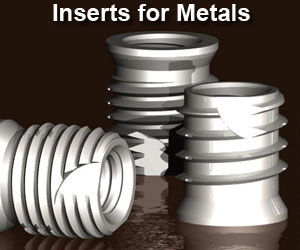

Inserts for Metals

Tappex® has acquired for over 60 years comprehensive knowledge of the application requirements of Threaded Inserts fastening across global industries. During the past 15 years, in particular, our range of self-threading inserts have been progressively developed to include new products necessary to meet the demands of the metals processing industries and more critical customer applications.

Such critical applications include: Castings, machined & sometimes fabricated parts produced from Light metal alloys i.e. Aluminium, Zinc & Magnesium. Our thread inserts have been extensively trialled and supplied to customers around the world, on land, sea, air & even in space. Our threaded inserts are of the self tapping type installed into either cast or pilot drilled holes to suit customer’s product manufacturing processes.

Trisert-3® - Self Threading Inserts

- Self Tapping inserts, in Steel (Case Hardened), Stainless Steel grades 303 and 316

- Trisert-3's incorporate a strong cylindrical-body, with three cutting facets and shallow flutes, this enables reliable installation into most light metal alloy(s). After consultation, Trisert-3's may also be considered for installation into hard and/or filled thermosets and some also some composites materials where a combination of thin sheet metal alloy and GRP/Foam/Wood-based 'in-fil' materials are specified

- Product range includes two primary designs: Reduced Headed and Regular Headed with two length variants. Trisert-3's head diameter is designed to exactly fit the corresponding counterbore in the prepared hole, and thus presents an acceptable flush fit, where required

- A key design feature is the inserts ability to operate in more harsh environments than a Brass insert including Food processing, Medical equipment and Marine applications whilst retaining good wear resistance and strength

- Like the brass Trisert®, the Trisert-3 range offers comparable installation cycle times and efficiency when compared to other post mold installation methods

- Normally open hole geometries but also Blind ended versions now available

- Trisert-3's may also be supplied with Tappex own design installation equipment which includes hand tools (031 series) and FlexiArm® pantograph with up to 3 Pneumatic, pre-adjustable torque limiting screwdrivers fitted (035 series)

Available in sizes Metric M2 to M10, with Unified and British Standard threads possible. More product & tooling information is available @ www.tappex.co.uk or please contact Tappex Head office and ask to speak with an applications engineer. Tappex has in-house design, development and manufacturing capabilities.