Threaded inserts for Engineering plastics

The Tappex Multisert® range of brass thread inserts for plastics has been developed to be a multi-purpose insert for a wide variety of industry applications; range includes four primary designs: Unheaded, Single Thickness Headed (at standard & reduced diameters) & Double Thickness Head. Lengths normally stated in mm.

Multisert® – Unheaded – Product Features

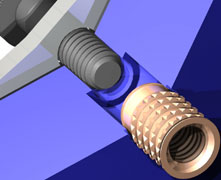

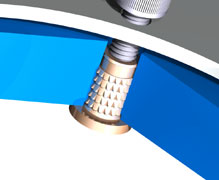

The most significant feature of the Mulitisert is its barb form that makes the insert suitable for different installation methods. The designer can therefore increase pull-out performance using the same insert by changing from press-fitting cold to heat or even ultrasonic insertion.

External barb form gives good flow characteristics and high pull-out performance.

Plain top ring gives a good bearing surface for mating components and traps any molten plastic forced upwards during insertion providing a clean flush fit (correct hole size must be used).

Free running internal thread – the insert is set in the plastic independently from the expansion action of the mating screw. This prevents rotation or screw breakage during assembly.

Plain location spigot and pilot barb ensures that the insert locates squarely in the drilled or molded hole prior to assembly.

Multisert® – Unheaded – Design Aids

- It should be specified for press-in applications in flexible thermoplastics, installation can be adjacent to the molding machine for operation efficiency

- It can be installed into most thermoplastics by heat or ultrasonics to give higher resistance to pull out loads

- It should be specified for small or medium volume usage where there are a limited number of inserts per molding

- It should be specified for high volume, single insert applications in small moldings

- It is available in two standard lengths to maximize choice, the barb form design makes it possible to manufacture non-standard lengths if customer applications cannot accommodate standard lengths

- To obtain maximum performance from the insert, the hole diameter in the mating part should be clearance for the screw thread-only. The mating part will then support the top face of the insert, which, in turn, reduces the possibility of rotation or ‘jack-out’ during final assembly

- It can be used as a pull-through insert where access to the rear of the plastic component is possible; recommended only where a stepped hole design is used as illustrated.

Multisert® – Single Thickness Head – Product Features

The Single Thickness Headed version of the Multisert incorporates all the standard features of the unheaded version but provides the designer and production engineer with three standard options to match product availability to common assembly situations not suitable to an unheaded insert. Large Diameter Head prevents jack out in applications where elongated slots or larger than standard clearance holes are necessary in the mating component. It has a larger bearing surface, which is required in high-torque applications. Two standard head diameters are available to provide for both performance and cost priorities.

Multisert® – Single Thickness Head – Design Aids

- It should be specified in applications where increased resistance to rotation is required. The insert can be installed by press-in or heat insertion; it is not recommended for ultrasonic insertion without consultation

- It also provides an excellent conductive surface for electrical contacts, ring connectors or eyelets

- All ‘Pull-through’ installations should be considered carefully and if in doubt please contact Tappex for more technical advice (this includes 071 & 072 variants)

Multisert® – Double Thickness Head – Product Features

The Double Thickness Headed version of the Multisert incorporates all the standard features of the unheaded insert but provides the designer and production engineer with a higher performance press-in insert for applications with through holes where access to the back of the component is possible.

Double Thickness Head can be used as a stand off or heat sink; it is possible to increase the head thickness still further, subject to quantities required.

Large Diameter Head for use in very soft materials where a smaller head diameter would pull through due to the flexing of the plastic.

Double Thickness Head – Design Aids

- The reduced head diameter short length versions (part nos: 072 & 073) should normally be specified in compact plastic materials as they have the lowest unit cost but in most rigid materials give very high performance. Use of a stepped hole similar to that when using un-headed inserts in pull-through applications will, where space allows, increase performance

- The regular length insert body (part nos: 005) should only be specified where there is a high push-out force prior to engagement of the screw

- Normally press-fit insertion is acceptable except when the assembly is subject to heat, vibration, drop tests or the plastic is stress prone and unfilled – if in doubt call Tappex

- All ‘Pull-through’ installations should be considered carefully and if in doubt please contact Tappex for more technical advice (this includes all 003 & 004 variants)

SELECT PRODUCT FEATURES

Please select the product dimensions and materials in the PRODUCT SELECTOR above.The following are downloads relating to the Multisert® range, although a download may also be applicable to other product ranges. General information can be found on our downloads page.

If you can’t find what you are looking for our helpful team are ready to assist you, simply give us a ring on +44 (0) 1789 206600.

Tappex Performance data of Inserts for Plastics in generic applications.

Tappex Performance data of Inserts for Plastics in generic applications.

Installing Multisert Brass Threaded Inserts Into Nylon Using The Tappex Heat Inserter Tool

In this video we demonstrate the ease at which Tappex’s Heat installer can be used to insert Tappex Multisert, Microbarb and Dedsert brass thread inserts into plastic.

No Video? ![]() Click the cookies icon below and accept cookies

Click the cookies icon below and accept cookies