M2-M8 Tappex production drivers

A range of specialist drivers with a torque release function for a wide range of professional threaded insert applications.

Key features

- Designed for use with the Tappex FlexiArm®, ElecArm®, tapping heads, portable air tools or by hand when used with a Production Driver Alignment Bush

- Able to function in conjunction with driving clutch of torque controlled air tools to release driver from the installed insert

- Available in a range of driver nose sizes for ideal depth control and to suit a range of space restricted or deep access applications

- Used in conjunction with Trisert®, Trisert 3®, Foamsert® and Ensat® self-tapping thread inserts.

Tappex Torque Release Production Drivers have been designed and tested to operate in a range of nose and stud configurations and with insert sizes from M2 to M10. The driving clutch can be configured to slip or actuate reverse when the nose of the driver bottoms out to ensure consistent depth control with ideal driving and release characteristics for the materials used.

We offer an Installation Tool Kit ideal for new projects, an ideal way to get started and begin fine tuning your manufacturing process. For full details of the specifications and details, please see our Torque Release Production Driver Spec Sheet.

Tappex offers a complete stock of replacement parts to ensure your tools keep going even under the heaviest workloads. Take a look at our suggested stock requirements (section 12.3)

Interested in our Torque Release Production Drivers?

Our specialist team are standing by to assist you in selecting the best option for your requirements and can share more detailed tips and troubleshooting advice than those on the spec sheet.

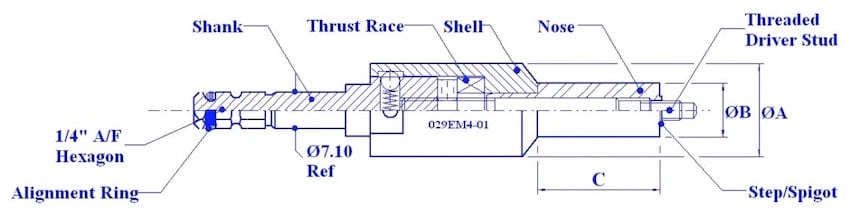

Tappex Production Driver identification and general dimensions

Regular standard nose production drivers

| Thread size | Part No. | A | B | C |

|---|---|---|---|---|

| M2 | 029EM2-01 | 19.0 | 9.0 | 16.0 |

| M2.5 | 029EM2.5-01 | 19.0 | 9.0 | 16.0 |

| M3 | 029EM3-01 | 19.0 | 9.0 | 16.0 |

| M3.5 | 029EM3.5-01 | 19.0 | 10.0 | 19.0 |

| M4 | 029EM4-01 | 19.0 | 11.0 | 25.0 |

| M5 | 029EM5-01 | 25.4 | 12.5 | 31.0 |

| M6 | 029EM6-01 | 25.4 | 16.0 | 38.0 |

| M8 | 029EM8-01 | 25.4 | 19.0 | 44.0 |

| M10 | 029EM10-01 | 31.7 | 24.0 | 57.0 |

| Thread size | Part No. | A | B | C |

|---|---|---|---|---|

| M2 | 029EM2 | 19.0 | 7.0 | 16.0 |

| M2.5 | 029EM2.5 | 19.0 | 7.0 | 16.0 |

| M3 | 029EM3 | 19.0 | 7.0 | 16.0 |

| M3.5 | 029EM3.5 | 19.0 | 8.0 | 19.0 |

| M4 | 029EM4 | 19.0 | 9.0 | 25.0 |

| M5 | 029EM5 | 25.4 | 11.0 | 31.0 |

| M6 | 029EM6 | 25.4 | 12.5 | 38.0 |

| M8 | 029EM8 | 25.4 | 16.0 | 44.0 |

| M10 | 029EM10 | 31.7 | 19.0 | 57.0 |

Spare studs are available for each length of Production Driver.

L1 studs suit short drivers, L2 studs regular drivers, and L3 studs long drivers.

Pointed studs should be requested when installing short-length inserts into hard materials and are essential when installing M8 inserts of 10mm or less with a Regular Length Production Driver. These can be specified by replacing the L with a P in the stud part number, e.g., in regular M4 stud, part number 029/L2/M4 becomes 029/P2/M4. This does not apply to special studs that suit special drivers.

When ordering a Regular Length Standard Nose Production Driver requiring a pointed stud, a P should be added to the end of the part number, e.g. regular M4 Production Driver, part number 029EM4-01 becomes 029EM4-01P.

| Prefix | Nose Length | For use with |

|---|---|---|

| 029A | Short | controlled slipping clutch tapping heads (square shank) |

| 029B | Short | air tools (hexagon shank) |

| 029C | Short | depth control tapping heads (square shank & extended spigot) |

| 029D | Regular | controlled slipping clutch tapping heads (square shank) |

| 029E | Regular | tools (hexagon shank) |

| 029F | Regular | depth control tapping heads (square shank & extended spigot) |

| 029G | Long | controlled slipping clutch tapping heads (square shank) |

| 029H | Long | air tools (hexagon shank) |

| 029I | Long | depth control tapping heads (square shank & extended spigot) |

| 029J | Regular | frictionless Production Driver for the jacking in of inserts using air tools (hexagon shank) |

| Thread size | Short nose length (029A, 029B, 029C) |

Regular nose length (029D, 029E, 029F, 029J) |

Long nose length (029G, 029H, 029I) |

|---|---|---|---|

| M2 | 1.60 | 16.0 | 38.0 |

| M2.5 | 1.60 | 16.0 | 38.0 |

| M3 | 1.60 | 16.0 | 38.0 |

| M3.5 | 1.60 | 19.0 | 38.0 |

| M4 | 1.60 | 25.0 | 38.0 |

| M5 | 1.60 | 31.0 | 38.0 |

| M6 | 1.60 | 38.0 | – |

| M8 | 1.60 | 44.0 | – |

| M10 | 3.20 | 57.0 | – |

Note: Longer length nose Production Drivers are available to special order only

| Thread size | Hex shank A/F |

|---|---|

| M2 | 1/4″ |

| M2.5 | 1/4″ |

| M3 | 1/4″ |

| M3.5 | 1/4″ |

| M4 | 1/4″ |

| M5 | 1/4″ |

| M6 | 1/4″ |

| M8 | 1/4″ or 5/16″ |

| M10 | 5/16″ |

| Thread size | A/F Square | Diameter | Length |

|---|---|---|---|

| M2 | 5.2 | 6.4 | 40 |

| M2.5 | 5.2 | 6.4 | 40 |

| M3 | 5.2 | 6.4 | 40 |

| M3.5 | 5.2 | 6.4 | 40 |

| M4 | 5.2 | 6.4 | 40 |

| M5 | 8.0 | 10 | 51 |

| M6 | 8.0 | 10 | 51 |

| M8 | 10.0 | 12.5 | 51 |

| M10 | 12.5 | 16 | 63.5 |

The following are downloads relating to Tappex Release Production Drivers. General information can be found on our downloads page.

If you can’t find what you are looking for, why not simply give us a ring on +44 (0) 1789 206600.

Production drivers for medium to high volume installation of Tappex self-tapping type thread inserts. Document includes identification guide, dimensions, suggested spares stock, and Troubleshooting guide.