Self -Tapping / Threading Thread inserts for critical applications

Trisert-3® – Features

Insert’s material grades

In most applications into plastic, the standard brass Trisert® offers a satisfactory and economic solution with good wear resistance and strength. Also it will withstand corrosion in most environments without any second operation surface treatment.

In order to meet the requirements of a wider range of host materials and harsher applications, the selection of the material for the Trisert-3® is very important. Trisert-3® inserts are offered in two grades of stainless steel (303 and 316) as well as a case-hardened steel variant with zinc nickel, trivalent passivated finish.

The stainless steel versions, in particular, are able to withstand critical operating environments, such as marine and chemical/food processing, while still retaining good wear resistance and mechanical strength.

Trisert 3® – Installation

The Tappex FlexiArm® provides a rapid and reliable method of installation for the Trisert-3® range. The FlexiArm® installation machine consists of a pantograph arm with a pneumatic screwdriver attached. The screwdriver can be specified with an automatic reverse torque-clutch control and operating at either 510 rpm or 1,100rpm. Alternatively, a manual reverse torque-clutch control operating at 510 rpm is available and will be recommended dependant upon the size of the insert and the material into which it is being installed.

The Tappex FlexiArm® provides a rapid and reliable method of installation for the Trisert-3® range. The FlexiArm® installation machine consists of a pantograph arm with a pneumatic screwdriver attached. The screwdriver can be specified with an automatic reverse torque-clutch control and operating at either 510 rpm or 1,100rpm. Alternatively, a manual reverse torque-clutch control operating at 510 rpm is available and will be recommended dependant upon the size of the insert and the material into which it is being installed.Hand Installation Equipment

Alternatively, the inserts can be installed by hand, using Tappex Hand Tools (031 range) that come complete with an alignment bush to ensure correct installation.

TRISERT-3® - REDUCED HEADED - 6238M3

These materials are RoHS compliant.

Finish: Self-Colour Passivated and as specified. Special finishes to customer requirements, at extra cost.

Description: The Trisert-3 is a single ended self-tapping insert. Its main features are the truncated external thread form with three equally spaced cutting facets.

Application: Designed to meet the the requirements of a wide range of host materials and harsh environments where brass Triserts would not be suitable. The Trisert-3 is compatible with the hole size for the equivalent size standard Trisert. Suitable in corrosive atmospheres and for installation into alloys or particularly hard engineering plastics.

Hole Size: Moulded and drilled hole diameters vary dependent upon installation technique, specific component geometry and material. Please consult our technical department for a precise recommendation, to ensure optimum production conditions. Sizes given are for reference purposes only.

Hole Design: The hole design information is intended to indicate the approximate dimensional requirements for satisfactory installation of the insert. They should not be specified for production tooling without prior consultation with our Application Engineering Department - we accept no responsibility should the use of this information without consultation result in product failure. Please call our application engineers for assistance +44 (0) 1789 206600

Installation: Self-tapping using a hand tool (part no.031) or reversible drive mechanism. Tappex offer pneumatic reversible tools mounted in a Tappex FlexiArm, used in conjunction with a Tappex production driver (part no.029).

We have also recently released our newest installation tool for threaded inserts, the ElecArm, a series of electric preset-torque screwdrivers mounted on balance arms, and can be used in conjunction with a Tappex production driver (part no.029).

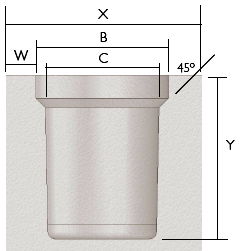

Hole Design

| Boss Diameter X: | 7.70 mm |

| Hole Depth Y: | 5.80 mm |

| Hole Diameter C (Alloys): | 4.35 mm-4.55 mm |

| Hole Diameter C (Plastics): | 4.10 mm-4.40 mm |

| Wall Thickness W: | 1.65 mm |

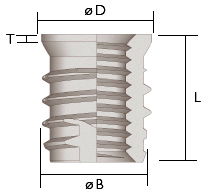

Insert Design

| Diameter (external) B: | 4.73 mm |

| Head Diameter D: | 4.70 mm |

| Head Thickness T: | 0.38 mm |

| Length L: | 5.25 mm |

| Part No.: | 6238M3 |

| Pitch (internal): | 0.5 |

| Thread Size: | M3 |

The following are downloads relating to the Trisert-3® range, although a downloads may also be applicable to other product ranges. General information can be found on our downloads page.

If you can’t find what you are looking for, please contact our experienced technical sales who available to assist you: +44 (0) 1789 206600.

Tappex 2018 Brochure

Product brochure with overviews and descriptions of products.

Threaded Inserts for Plastics a ten point guide

Tappex brochure about the Trisert-3® range of Tappex products. Overview, applications and technical specifications

Features and Description of the Tappex FlexiArm

Details of Production Driver Function, Identification, Dimensions, Suggested stock, and Troubleshooting.

Tappex Hand Tool description, instructions for use, and maximum torques.

Installing Trisert 3 (Stainless Steel Threaded Inserts) Into Nylon

In this video we demonstrate the Tappex 510rpm Manual Reverse Pneumatic Screwdriver & Flexiarm and show how easy it is to install Tappex’s Trisert-3 (one of our stainless steel self threading inserts) into 30% glass filled nylon.

No Video? ![]() Click the cookies icon below and accept cookies

Click the cookies icon below and accept cookies