Prototal & Tappex – Enabling Reliable, Production-Ready 3D Printed Components

Prototal is a leading provider of polymer production solutions, specialising in additive manufacturing, injection moulding, vacuum casting, and associated aluminium tooling.

With a strong presence across multiple sectors — including aerospace, automotive, defence, drones & UAVs, medical, and motorsport — Prototal delivers both prototype and full-scale production components to some of the most demanding industries.(EV) battery systems, specifically for highperformance automotive applications.

The challenge:

As additive manufacturing continues to mature, customers increasingly require end-use 3D printed parts that can withstand real-world mechanical demands. For Prototal, this meant finding a reliable and efficient method of adding threaded inserts to their SLS-printed components, jigs, and fixtures.

Before partnering with Tappex, Prototal’s team faced challenges with manual tapping across multiple parts — a timeconsuming process that slowed production and introduced variability in assembly quality. They needed a faster, more consistent installation method that would ensure strong, repeatable threads for their polymer-based parts.

The Solution

Prototal partnered with Tappex Thread Inserts Ltd, a UK-based specialist in threaded insert technology, to identify the most suitable insert types and installation process for their additive manufacturing workflows.

Working collaboratively, Tappex provided technical consultation and product recommendations based on each customer’s application. The selected Tappex inserts were integrated into SLS-printed end-use parts, functional jigs, and fixtures, offering a durable and professional fastening solution.

To optimise installation efficiency, Prototal adopted the Tappex Elecarm – a precision electric installation system designed for repeatable and ergonomic insert installation. This move allowed the team to maintain a clean, controlled workflow and reduce human error in production.

“The choice of insert is customer-driven, with guidance from Prototal and Tappex to ensure the best fit for the application.” — Prototal Technical Team

The Results

By incorporating Tappex threaded inserts into their production processes, Prototal now provides customers with fully finished, production-grade components that are robust, reliable, and ready for assembly.

The partnership has delivered:

- Reduced production time thanks to simplified installation.

- Improved assembly robustness and repeatability.

- Lower overall production costs due to decreased rework and faster turnaround.

- Enhanced customer confidence in the mechanical performance of 3D-printed parts.

“Tappex products give us the ability to provide fully finished production parts which are robust and reliable, saving production time in assembly and ultimately reducing cost.”

Technical Collaboration

Prototal praised Tappex’s technical expertise and support, particularly in helping to integrate the Elecarm system into their workflow.

“Tappex’s knowledge base and technical advice are enabling the introduction of new technologies such as the Elecarm, helping us expand our capabilities even further.”

This partnership exemplifies how strong supplier collaboration can drive innovation and efficiency within advanced manufacturing.

Looking Ahead

Threaded inserts have now become a standard feature in Prototal’s additive manufacturing workflows. As demand for production-ready 3D printed parts continues to grow, Prototal expects to expand the use of Tappex solutions across future projects — ensuring their parts remain functional, durable, and ready for end-use assembly.

“Threaded inserts are used extensively in production, complementing traditional assembly fixtures”

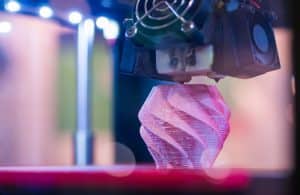

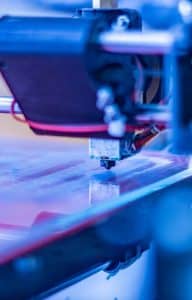

Visual Example

Across, are examples of SLS-printed components fitted with Tappex brass inserts, demonstrating the clean finish and robust integration achieved through the partnership.

About Tappex Thread Inserts Ltd

Tappex is a UK-based manufacturer with over 70 years of experience designing and producing high-quality threaded inserts for plastics, metals, and composite materials. With an emphasis on engineering support and innovation, Tappex helps manufacturers across industries achieve stronger, more reliable assemblies.