Threaded Inserts for 3D Printed Products or Prototypes

Tappex® are often asked the question…

“Which thread insert should I use in my 3d printed prototype”

Before we answer this question, firstly perhaps we can consider…

Why use a Thread Insert?

With more and more manufacturers/OEM’s looking to utilise additive manufacturing processes/3D printing technologies, for both low to medium volume production and prototype parts, high quality fixings and threads are becoming a necessity in these plastic parts.

Holes in plastics can be drilled and tapped to produce a thread, however the thread will likely be weak and there will always be the risk of cross-threading.

Thread forming screws can be used, however they generally only allow the screw to be installed and removed a couple of times before the hole in the parent material fails, which means the screw can no longer grip and provide the necessary clamping torque.

Threaded inserts installed into 3D printed products can offer a better simulation of exact application conditions, thus allowing the user to establish if the thread size is large enough to meet the specified performance requirements.

How to use a Thread Insert

There are a number of insert styles that can be used with 3D printed prototypes.

Tappex® – Trisert® Self-tapping Thread Insert.

The most commonly used is the Trisert® range of self-tapping inserts. The Trisert® range of brass thread inserts are an excellent general-purpose insert that offers both very good rotational and pull-out performance and doesn’t require costly installation equipment to install. The Trisert® self-tapping inserts will tap their way into most engineering plastics (filled or un-filled thermosets and thermoplastics). We also manufacture a range of case-hardened steel and stainless steel Triserts®, should your application have environmental considerations. For more information on the stainless steel Trisert 3s® please click here.

For very low-volume applications, Trisert® thread inserts can be installed using a nut and bolt. For further information on how to do this, click here.

Tappex® manufacture (in-house) a range of hand tools to suit the Trisert® range of thread inserts. Generally available from stock, our hand tools offer an in-expensive installation option for low to medium volume applications. The hand tools will ensure correct, consistent and repeatable installation of the Trisert® thread inserts.

For more information on our range of hand tools, please click here, alternatively we have a YouTube video of the tool in action here.

Tappex Flexi-arm Installation Machine.

The Trisert® is also a good choice of insert, if volumes are likely to increase. They are very competitive in price and for higher volume applications, we offer the Tappex® Flexi-arm installation machine. For more details of the machine click here, alternatively you can see the machine in action, on our YouTube channel here.

Tappex Multisert Thread insert – for cold press/ultrasonic or heat installation into thermoplastics.

Multisert® inserts are also a general purpose insert and can be cold pressed, heat installed or ultrasonically installed into a wide range of engineering thermoplastics.

One thing to consider when planning to use the Multisert® insert, is whether the 3D printed product can be held flat whilst the insert is pressed/installed into the parent material. Sometimes it can be difficult to ensure that the molding is held perpendicular to the insert during installation.

Installation Tooling for Multisert® Thread Inserts.

Multisert® thread inserts can be installed using a Fly press, Arbor press, Tappex® heat inserter, or even in some cases a soldering iron can be utilised. For more information on the Tappex® heat insertion machine, please click here. We also have a video of the machine in action on our YouTube page here.

This is not something that we recommend, however, in some cases our customers have been known to drop an insert into an oversized hole in the parent material, with a drop of superglue.

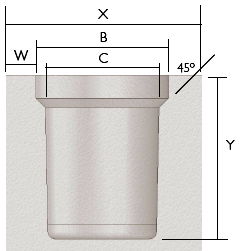

Hole Dimensions

The Tappex® website offers a guide to hole dimensions for each of the inserts that we offer. The hole size required in the material will vary depending upon the parent material. You will also need to take into consideration the tolerance for the 3d printing machine that you are using.

Whilst the website offers a good guide, we’d strongly recommend that you contact us directly to obtain a hole size drawing, specific to your chosen material.

What if I have any further questions or need assistance with my application?

As a UK manufacturer, trading since 1956, Tappex® offer extensive technical support, from design stage, right thorough to series manufacture. In the first instance, small numbers of samples can be provided for prototyping purposes, and prior to manufacture we have in-house applications engineers that can perform pull-out, or application torque tests to confirm suitability of the thread inserts for your chosen application.

Where can I get high quality UK manufactured thread inserts from?

Tappex® Thread Inserts are located on Masons Road, Stratford-Upon-Avon, Warwickshire, CV37 9NT. Click here to find us on Google maps…

We can accept card or BACS payments from consumers or trade customers alike.

Tappex® ship products, directly to OEM’s across the globe, alternatively we have a long established global network of technical distributors, of which you can find further details on our website here.